Basic characteristics of chromium carbide powder;

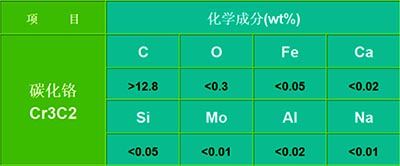

1) Chromium carbide is dark gray powder, which is made of metal chromium and carbon by vacuum carbonization. Its molecular formula is Cr3C2 (theoretical weight percentage of carbon is 13.4%), and its structure is rhombic.

2) Chromium carbide is insoluble in water and can resist acid and alkali.

3) Chromium carbide is an inorganic material with good wear resistance, corrosion resistance and oxidation resistance at high temperature (1000-1100 degrees), and is widely used as a thermal spraying material for metal surface protection.

4) Chromium carbide is also commonly used as grain refiner of cemented carbide and other wear-resistant and corrosion-resistant components.

5) Cermets based on chromium carbide have excellent oxidation resistance at high temperature, and the surface only darkens slightly after exposure at 982℃ for 5 hours. However, under the same conditions, the 18-8 stainless steel has been significantly damaged, while the WC-6Co alloy has been completely oxidized.

Main uses of chromium carbide powder:

1) Chromium carbide is used as special welding material.

Can be used for manufacturing special welding materials, surfacing series covered electrode, flux-cored wire.

2) Chromium carbide is used in cemented carbide.

Adding Cr3C2 in cemented carbide production can not only refine WC grains, but also improve the strength and hardness of the alloy, and significantly improve the corrosion resistance of the alloy.

3) Chromium carbide is used for thermal spraying powder materials.

By plasma spraying, a coating with high wear resistance, corrosion resistance and high temperature resistance can be obtained by adding alloy powder of NiCr superalloy based on Cr3C2, which is widely used in fan blades, boiler “four tubes” and so on.

4) Chromium carbide is used for arc spraying wire and submerged arc welding tubular wire.

Cr3C2 material is added to arc spraying wire, which improves the high temperature resistance and wear resistance. It is applied to the repair and preventive protection of boiler “four tubes”, the wear-resistant lining plate of iron-making distribution chute in metallurgical industry, and the preventive protection of pipe welding wire produced by adding Cr3C2 to coal grinding roller in power plant, which greatly improves the service life.

Reviews

There are no reviews yet.